Ferrules Detail

Site Navigation Menu

![]()

Email: AV Young avytasmania@gmail.com

AV Young ferrules and reel seats are made from an alloy of copper, nickel and aluminium called Nickel Aluminium Bronze (AMS4640).

By comparison Nickel Silver is not considered to be a particularily strong material, however when the right alloy is drawn it can be a

moderate to strong material depending upon its alloy and degree to which is is drawn.

An advantage that NS has over AMS4640 from the manufacturing point of view is that being essentially a brass it can be cold formed and it

can be soldered and being softer it is able to be machined much easier and faster than AMS4640. It also costs less than AMS4640.

Due to the aluminium content of AMS4640 cold forming isn't possible. Aluminium contrary to what you may imagine is a very stiff material

in this alloy so it prevents cold forming.

This aluminium oxide is a good thing though because it helps prevent corrosion of the alloy.

Some of these properties, desireable as they are in the finished ferrule complicate manufacturing and necessitate them being machined.

However, all of this together means that the resulting ferrules made from AMS4640 are lighter, stronger and more corrosion resistant than can be made using NS in any form at all, be it rod or tube.

Although the ferrules initially look almost the same as NS in colour they do in time take on a bronze colouration they can be blued using the same bluing

formulas as used in bluing NS.

Comparing AMS4640, Duronze (C64200) and NS you can see AMS4640 is the stronger of all the alloys listed in the following chart of nominal strengths and just

below it mass:

Alloy............Tensile MPa......Yield MPa

Clearly AMS 4640 is the outstanding material and it has largely superseded Duronze in most of the aerospace applications it was used for in the past.

As well as this AMS 4640 is 13% lighter than 18% NS while being around 15%-20% stronger. In my opinion it is the best material to make ferrules from.

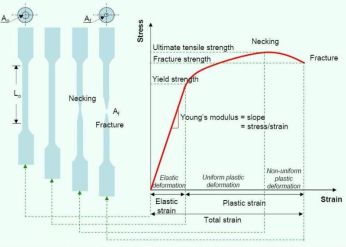

Strength of materials wise, at its most basic the Ultimate Tensile Strength (UTS) is the greatest resistance to a force applied to a material that it may withstand before it fails in tension while the Yield is the force required to cause the material to enter its plastic deformation stage on the way to its UTS just before it fails.

Once the forces have exceeded the UTS of the material it will continue to deform requiring less force to do so until it fails.

Special note must be made for Nickel Silver because of the way the ferrules are made.

1stly it's difficult to give accurate figures for NS as the term Nickel Silver covers a whole range of different alloys varying in the amounts of nickel which is where it derives it's strength from less than 12% to 18%. Aluminium bronzes derive their strength mainly from the aluminium content with the nickel adding further strength.

Also, the term drawn covers a lot as it could be 1/4, 1/2, 3/4 or fully drawn and each will have it's own yield point because each is at a different stage of reaching the UTS.

Drawn ferrules or ferrules made of drawn tube by definition place the ferrules inside of the plastic deformation curve Yield point but short of the UTS.

Fully drawn NS is very close to the Ultimate Tensile Strength of the material and while it has not yet reached the Ultimate Tensile Strength of the material it is close to it.

This is why well designed drawn ferrules of nickel silver are stronger than machined nickel silver ferrules, even if the alloys are identical which they normally aren't.

The machined NS ferrule hasn't yet reached its Yield stage when made, but having a relatively low yield point reaches it in use allowing the ferrule to become loose in time.

However for a drawn NS ferule to be strong enough to work well it also has to be drawn to close to its UTS.

But AMS 4640 is the strongest material of all listed drawn or machined.

As noted, the downside to using AMS 4640 is that it's un-suitable for cold forming or reliable soldering so it must be machined and maching it is realtively slow going.

The up side is that there are no solder joints at all and because its strength is superior to fully drawn 18% NS the ferrule is stronger even though it is machined.

Obviously, NS works, it always has but for all of these reason I believe that Nickel Aluminium Bronze makes the superior ferrule and the extra few

dollars that it costs over NS due to the relative difficulties in machining it is not that much. Since the ferrules are machined I'd rather use

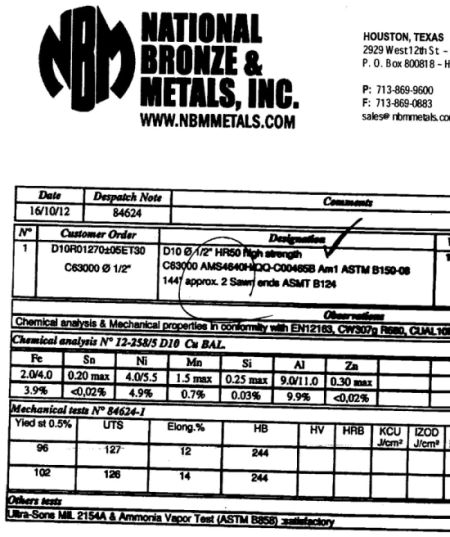

AMS 4640 than Duronze. Also I can be assured of always obtaining the correct alloy because it is an aerospace standard material and when I buy it I am provided with an annalysis report of each batch I buy. An example is below with Yield and UTS shown in ksi (1 ksi = 6.879MPa):

AMS4640 alloy is a reasonably new alloy used extensively in the aeorspace, mining and naval industries and was designed to be a very stong, highly corrosion

resistant material that has excellent wear properties including use in self mating situations such as bushings, bearings and prop shafts.

Also, due to the aluminium content, almost immediately upon cutting a fresh surface a microscopic layer of aluminium oxide forms and

this prevents soldering.

AMS 4640.............760.............470

Duronze C64200 ....620.............310 AKA AMS 4631 THE Duronze

Duronze C95400 ....655.............310

NS Rod CA754........434.............220

NS CA752 18% FULL DRAWN Tensile MPa 655

NS CA752............ 0.316 lb/Cubic inch

AMS 4640.............0.274 lb/Cubic inch

AMS 4640 as already stated can also be blued just like NS using most of the same solutions.

Because of this I have shown a NS of 18% nickel that is used as rod stock as well as fully drawn to allow a best case comparrison.

To alievate this problem machined nickel silver ferrules may be made thicker walled than you would make them from tube making them heavier.

The drawn ferrule is already beyond the Yield point closer to the UTS so stronger.

The nominal UTS of AMS 4640 is about 20% higher than Duronze and fully drawn 18% NS.

As you can see this particular batch shows a Yield of 661MPa and UTS of 868MPa.